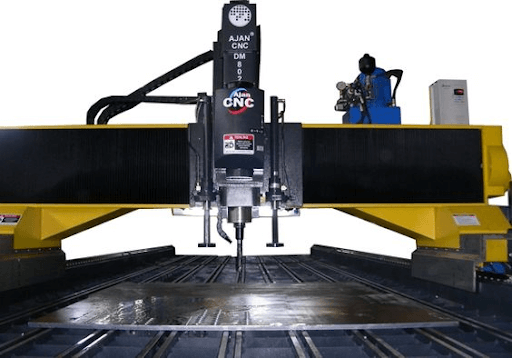

CNC machining for digital manufacturing is in great demand. Its primary advantages of high accuracy, inexpensive initial investment, and a diverse armament of strong materials make it an appealing alternative for one-offs, prototyping, and low to moderate production series.

Improvement is the big thing whether you are a beginning CNC machining firm or been in business for a long time. With a crowded market packed with many huge, well-established rivals, it might be difficult to hold your own and develop beyond your competitors, but it is possible. We’ve got six basic ideas for starting a CNC machine business or growing an existing one.

Plan

If everything goes well and the employees remain enthusiastic and dedicated, a firm will naturally blossom towards wealth. However, it all begins with a solid company strategy.

A business plan is similar to a marketing strategy, except that your firm is the product. It covers a wide range of topics, from the quality of product to pricing tactics to customer service.

Successful business strategies involve focusing on the sorts of customers who are likely to buy your items in large quantities. If your CNC shop specializes in creating smaller dimension gear shafts, it’s a great way to build partnerships with customers who buy them in bulk. Identifying a target market allows you to use your speciality more effectively, reducing both wasted effort and lost money.

Begin slowly.

While you may be anxious to buy new machinery or expand your facilities, doing so without sufficient planning or personnel can eventually slow down your company’s growth and hinder your long-term growth. In the long term, it is considerably more useful to focus on modest steps that promote moderate and steady progress rather than making massive scale leaps forward.

Instead of instantly jumping on the high-tech wagon like investing in a tin packaging machine, evaluate what may be accomplished with only the minimal needs. It’s frequently preferable to run a tiny 3-axis machine alongside a standard lathe from the garage rather than investing everything in costly, cutting-edge 5-axis equipment and renting a studio downtown.

In the long term, it is considerably more useful to focus on modest steps that promote moderate and steady progress rather than making massive scale leaps forward.

The Demand must Be Followed.

Branching out and developing new items is a fantastic method to start and expand your company, but expanding to grow your firm without thoroughly evaluating market needs can lead to disaster. Have you seen what manufacturing is booming and what is stalling, and expand in methods that will shield you from market shrinking?

For instance, if you have an enterprise and funding to add lucrative Seaskymedical medical molded products or plastic fabrication business, well-planned variety may help you continue your development even when one of your products is in decline.

Be Receptive to Technological Advances

Although new technological advances might be expensive in terms of advanced training and initial supply, newly invented equipment like medium voltage vacuum contactor may have a favorable long-term impact by simplifying production procedures or offering the ability to execute jobs that were previously thought unfeasible. New technology may occasionally help a company stay competitive, especially if the invention is widely publicized.

For some years now, tech has been fast progressing at an astounding rate, and you may be turned off by the continual change and financial expenditure necessary in the retraining and set-up required to integrate new technology to your operational processes. Investing in new technologically sophisticated software and technology, on the other hand, may enable your factory do things that were previously impractical or even impossible, allowing you to stay viable in a forward-thinking industry.

Create Long-term Partnerships.

People are comparative beings. It is critical to win their approval and regard in order to establish a reputation. Building extensive expertise is less necessary for a starting firm than social connection and sales abilities.

To begin, look for links in your existing professional and personal networks. Attend trade shows. Create a growth strategy centered on these connections, and plan ahead. Keep in touch with your connections and grow on current contracts by mailing newsletter updates and considering new prospects for components that have been accepted into the manufacturing industry.

Concentrate on Needs

Pay attentive attention to your consumers’ demands. This is particularly true for CNC machining firms that specialize in a certain sort of service. For instance, if your personnel have gotten more than one form of expert service training, you may choose to take on many projects rather than just one. By expanding your service outside your speciality, you might prevent losing revenue in a department as a result of decreased client demand.

Conclusion

You may always employ the above tried-and-true recommendations and suggestions in this market to help your firm flourish.